When you turned on your tap and noticed the water looked odd or smelled strange, this may be an alarming indicator that the clean water that you have been using is mixed with contaminated water. This is a dangerous condition and is referred to as backflow. Although it is a technical sounding, once you are familiar with the basics that will enable you to protect your home or business. For residents seeking reliable backflow testing services in Cabot, AR, knowing what to look for is the first step toward a safe water supply.

Understanding How Backflow Occurs in Plumbing Systems

To begin with, it is necessary to know why this happens. Water usually flows in a single direction, that is, the supply of the city towards your house. Nevertheless, sudden changes in pressure can reverse this flow. Once this backflow occurs, then irrigation as well pool or industrial equipment water may become contaminated and be pumped back into your drinking water pipes.

To prevent this, the plumbers install certain backflow prevention systems. Such devices are one-way gates. They permit the water to flow in and prevent its backward exit. One of the major risk areas is a plumbing cross connection. This happens at any point where your clean water pipes are physically attached to an outlet of pollution such as a garden hose in a soapy bucket. These connections would be accidents that occur without protection.

Most Common Backflow Problems Found During Inspections

The best equipment gets worn as time goes by. In the process of regular inspections, specialists tend to discover certain problems undermining safety. Backflow valve failure is one of the common issues. The springs and seals located within the preventer may break down, i.e. the gate does not close up tightly enough to exclude contaminated water.

The other usual offender is pressure imbalance issues. When the street is broken by a water main or the fire hydrants are turned on in the neighborhood, the resultant vacuum in the city lines is caused by the sudden loss of pressure. Such vacuum drags your dirty water in reverse through your pipes. And when your preventer is faulty, either by debris or wear, it will not be capable of managing this change of pressure.

How Certified Testing Detects Hidden Backflow Risks

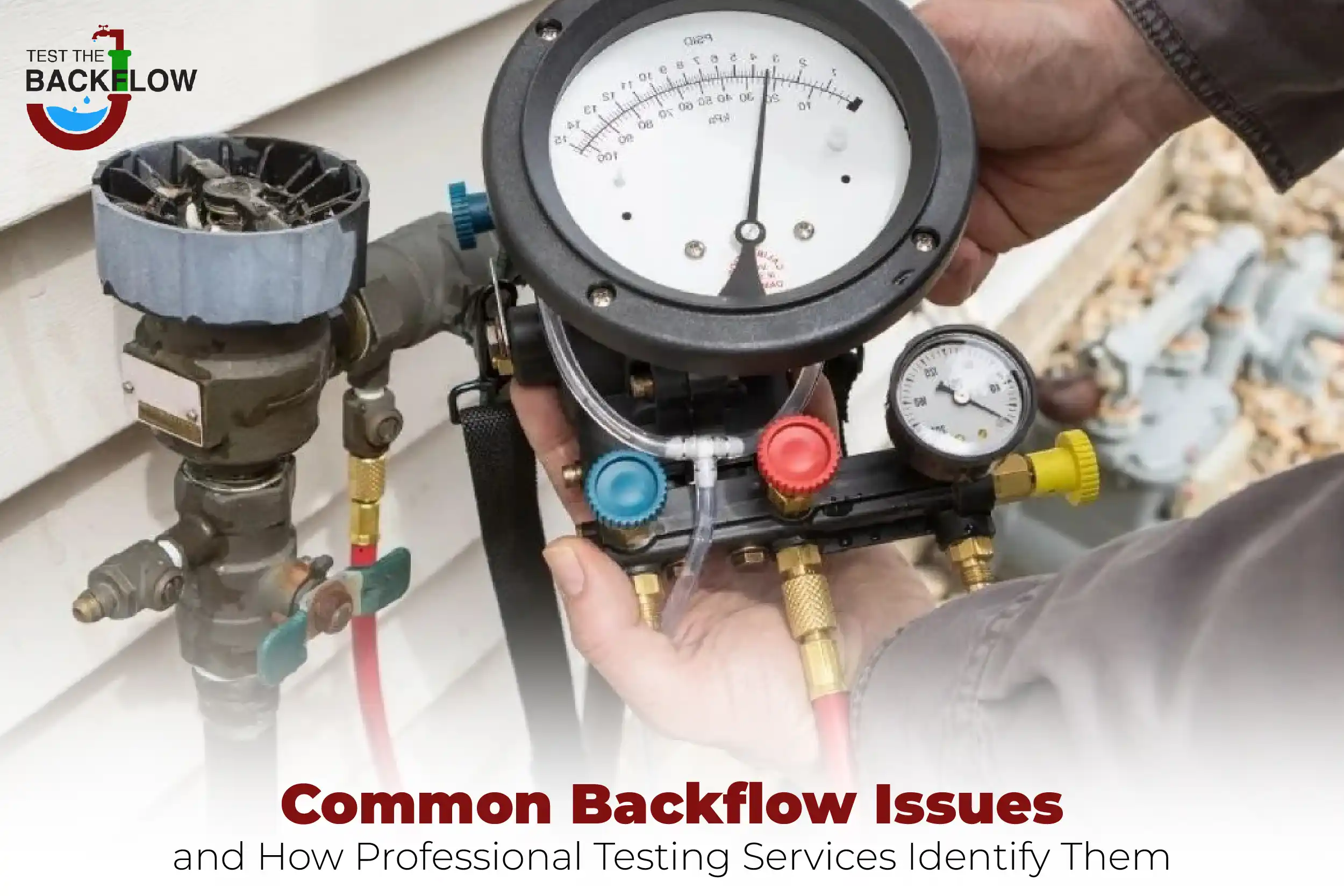

Backflow is not always visible or palpable. It is the reason why certified backflow testing is a legal requirement in most places. A qualified tester is linked to your prevention assembly and to gauge equipment that is specifically made.

They pass water through the machine to gauge the disparities in pressure across the valves. These backflow inspection procedures are accurate. The tester makes sure that internal check valves are tight against back pressure and that air inlet values open at the right time. This procedure detects any underlying leakages or mechanical breakdowns which would be totally missed by a visual examination.

When Testing Results Indicate the Need for Backflow Repair

In some cases, a device fails to pass the test. Once it occurs, you must take immediate action to remain legal and safe. In the case of backflow repair services in Cabot, AR, the unit can often be disassembled by a professional in order to clean it or change the worn rubber components.

Cleaning often fixes the issue if debris was preventing a seal. But when the metal body is broken or the springs shot, then it cannot be repaired easily. Backflow device replacement is required in such cases. Purchasing new equipment will guarantee that your water is clean, and your property is up to standard.

Clean water is essential for your health. Do not wait for a contamination emergency to think about your plumbing safety. Usual testing gives you peace of mind. For expert help and reliable service, you can contact Test The Backflow today to schedule your annual inspection.